ISCRIZIONE NEWSLETTER

"*" indicates required fields

MARCEGAGLIA TRISIDER

Established in 1974, in 1983 it became part of the Marcegaglia group, the European leader, and among the world leaders, in the processing of steel. Trisider has pursued a programme of constant development and expansion reaching the position of market leader in the distribution of steel in the north-east of Italy, with an annual volume of more than 30 million Euros and a dozen vehicles in its motor pool.

High quality levels and a wide range of products together with a service aimed at maximising efficiency guarantee customers the perfect response to any new requirement.

PRODUCTS

QUALITY AND LABORATORY

PRINCIPAL CORROSIVE PHENOMENA

The effective design of products manufactured from stainless steel should take into account any corrosion that may occur in its use.

To this end there is a Customer Service Centre at the Forlì plant working in collaboration with the Italian Stainless Steel Development Association to provide technical advice on the best choice of materials and their correct use.

- General corrosion

- Stress corrosion cracking

- Galvanic corrosion

- Intergranular (or interchrystalline) corrosion

- Pitting

- Crevice corrosion

- Cold drawn pipes for cardans

QUALITY AND TESTING

PRINCIPAL NON-DESTRUCTIVE CONTROL SYSTEMS USED

- Eddy Current Control (Sep 1925 – Sep 1914)

- Hydraulic test

- X-rays

- Penetrant testing using liquids

GENERAL PRODUCTION PLANNING

The welding methods used in Marcegaglia’s plants are carefully selected based on the product’s intended final use to offer the best physical and mechanical characteristics as well as resistance to corrosion.

STAGES OF THE PRODUCTION PROCESS

– Rolling

– Austenisation and coil pickling

– Tube forming and welding

– Tube austenisation furnace

– Rolling of environmental pipework

– Non destructive Eddy Current Testing

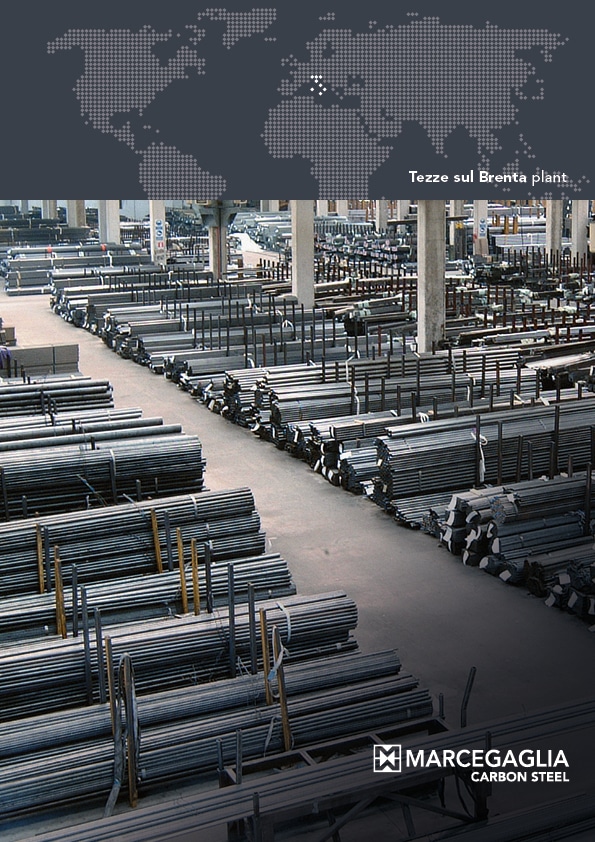

MARCEGAGLIA TRISIDER – Tezze sul Brenta

via Basse, 15

36056 Tezze sul Brenta

Vicenza – Italy

phone +39 . 0424 535 400